DAT’Process

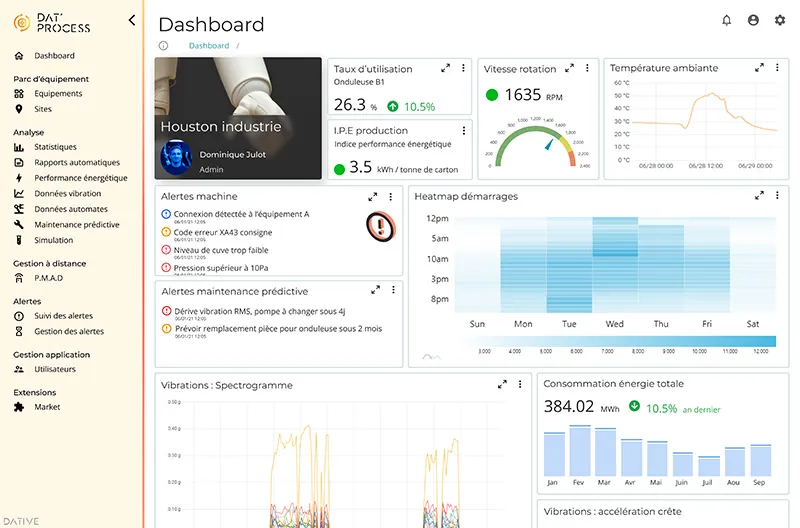

Industrial monitoring dedicated to the tracking and optimisation of processes and maintenance

Monitor the state of health of your production tools in real time and analyse specific process data.

DAT’Process is a monitoring solution dedicated to the management of industrial sites and to maintenance and technical department managers, enabling the collection, aggregation, and analysis of process data (operating cycle, production, vibrations, oil quality, and other data influencing your manufacturing).

Monitoring

Real-time data collection

Process data

- Motor (temperature, speed, torque, etc.)

- Vibrations

- Oil quality

- Cycling rate of machines

- Consumption of raw materials (e.g., starch, steel, etc.)

- Other data influencing your manufacturing

Integration

- Connection with supervisors and PLCs

- Connection with the CMMS (spare parts, last maintenance date, …)

- Retrieval of production recipes

Analysis

Analysis of specific process data

Process

- Detection of operating cycles

- Detection of operating patterns to find production optimums

- Anomaly detection and smart alerts

- Comparison of data with Abacus

Maintenance

- Detection of the ageing of parts

- Identification of the causes of malfunctions

- Creation of intervention requests in the CMMS in the event of anomalies

- Anticipating faults and troubleshooting aid

If you have a project and would like to discuss it with our team, please get in touch!

Contact us

Technical

Specialist experts at your disposal

- Mastery of a wide range of sensors suited to the world of industry

- Instrumentation and installation by industrial maintenance specialists (GPI subsidiaries)

- Specialist experts in Maintenance Methods, Vibration, Machine Safety, and HV/LV Maintenance (GPI Experts)