Case Study: NINKASI

NINKASI adopts the DAT’POWER solution and achieves real savings in record time

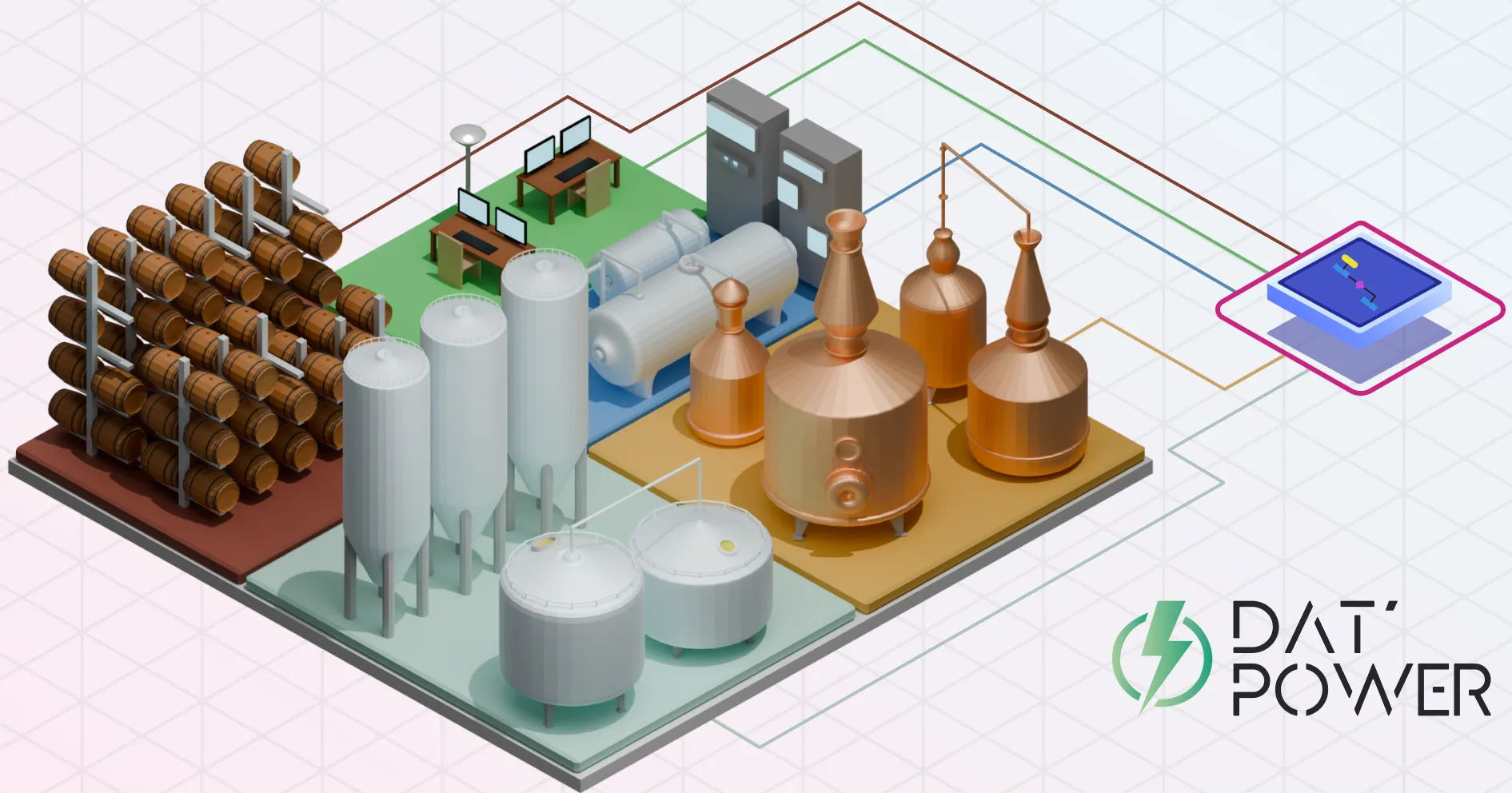

Discover how DATIVE transformed the energy efficiency of NINKASI's new production site with a complete solution, integrating ERP production data, energy usage instrumentation, and intelligent alarms. A turnkey project that delivered savings within the first months while ensuring rigorous energy performance tracking.

NINKASI's Energy Challenge

When launching its new production site in Tarare, NINKASI set an ambitious goal: improve energy efficiency without compromising production quality. This is where DATIVE's DAT'Power solution came in, centralizing consumption data and providing real-time energy performance monitoring.

A Turnkey Solution with Immediate Results

DAT'Power allowed NINKASI to gather all energy data through a single interface. This project optimized water, gas, and electricity consumption across various production lines. Significant savings were achieved within the first weeks by identifying inefficiencies and leaks.

Testimonial: Rapid and Measurable Success

With the start-up of our new production site in 2023, we wanted to take a significant step in improving our energy consumption. Being aware that we can only improve what we measure, we were attracted by the DAT'Power solution which allows us to bring together on a single portal all of our production data, water consumption, gas, electricity and other utilities that we use to make our beers and whiskeys. The extensive technical support, the quality of the DATIVE teams, the flexibility of the solution, as well as the speed of deployment, allowed us to retrieve a maximum of information already available on our equipment, and to judiciously install a minimum of new sensors. The economic impact was rapid, because we were able to use this data to best adjust our newly installed utilities, and the very flexible alert system allows us to provide rapid responses to leaks and other performance problems inherent to any new production site.

- Amaury FREYSSENET, Spirits Production Manager

Multi-system integration: A tailored solution for NINKASI

One of the key strengths of our project for NINKASI was DAT'Power's ability to seamlessly integrate with the existing systems. We connected industrial controllers, boiler supervision systems, and integrated ERP data to centralize all critical energy information. This robust architecture enables NINKASI to efficiently monitor and manage all its energy flows.

Energy performance indicators and smart alerts

With DAT'Power, NINKASI benefits from energy performance indicators (EPI) specific to each activity sector, coupled with smart alerts. This system detects and corrects anomalies in real time, optimizing energy consumption and ensuring cost savings from the very first months.

Technical support and customization

Every project is unique. For NINKASI, we customized DAT'Power to meet their specific needs. This included separating energy consumption by activity (brewery, distillery, etc.) and analyzing the costs per energy type and usage. This level of detail enables NINKASI to optimize processes while precisely managing costs.

Conclusion: A fruitful collaboration for concrete results

Thanks to our DAT'Power solution, NINKASI not only improved its energy efficiency but also achieved substantial savings within the first weeks. This project demonstrates how a tailored approach and real-time monitoring can transform energy management for industrial companies. Contact us to learn how we can support your own energy performance projects.