Industrial Compressed Air Optimization: The Guide

Compressed air is an essential resource for many manufacturers. Used in a wide range of applications-from pneumatic tools to production line automation-it’s often considered the “fourth utility,” after electricity, gas, and water. However, it’s energy-intensive: according to the French ecological transition agency (ADEME), compressed air can account for up to 10% of the electricity consumption of an average industrial site. In some sectors, this share can even reach 30%. Optimizing energy consumption related to compressed air is therefore a key lever for improving overall performance and reducing operating costs. In this article, we’ll explore the challenges of compressed air, key performance indicators, and solutions to improve its energy efficiency.

What Is the Purpose of Compressed Air in Industry?

Compressed air is used in a wide range of industrial processes. It powers essential tools and equipment that keep production lines running smoothly. Key applications include:

- Pneumatic tools: used for screwing, drilling, sanding, or grinding-especially in the automotive and metal industries.

- Process automation: cylinders, actuators, and conveyor systems often rely on compressed air for their speed and reliability.

- Cleaning and blowing: frequently used to remove dust or debris from parts or production lines.

- Pneumatic conveying: in food processing or chemicals, it allows powders or granules to be transported without mechanical contact.

- Control and regulation: some measurement or safety systems use compressed air as an actuation medium.

Versatile, clean, and easy to store, compressed air is therefore a strategic industrial utility—often essential for smooth operations.

Why Optimize Your Compressed Air System?

While compressed air is a useful and flexible resource, it’s also one of the most expensive forms of energy to produce. Optimizing your system offers several major benefits:

- Reduced energy costs: compressed air production is energy-intensive. An undersized or poorly maintained system can lead to significant overconsumption.

- Improved reliability: an optimized system is less prone to pressure fluctuations or breakdowns, ensuring continuity of service.

- Extended equipment lifespan: minimizing unnecessary load on compressors and the network helps reduce premature wear.

- Lower environmental footprint: consuming less electricity also means reducing associated CO₂ emissions.

- Regulatory compliance and financial support: some optimization efforts can be supported by schemes such as Energy Savings Certificates (ESCs).

Optimizing your compressed air system isn’t just a technical issue-it’s a strategic lever to enhance your company’s competitiveness and sustainability.

Key Performance Indicators for Industrial Compressed Air Optimization

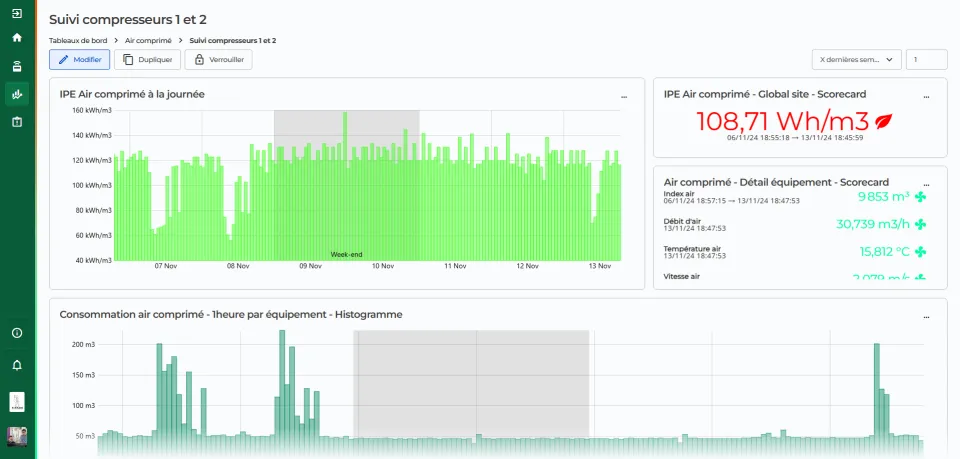

To control compressed air consumption, it’s essential to monitor key indicators, such as:

- Compressor efficiency: this measures the effectiveness of converting electrical energy into pneumatic energy. Low efficiency indicates internal losses (heat, friction, mechanical resistance).

- Leak rate: expressed as a percentage of the air produced, this reflects losses caused by leaks in the distribution network.

- Average network pressure: excessive pressure increases energy use and leak risks. Pressure should be optimized to meet actual application needs.

- Specific energy consumption (kWh/Nm³): this tracks the energy required to produce one normalized cubic meter of air. Regular monitoring helps detect inefficiencies early.

Contact us to optimize your compressed air system

How to Monitor These Indicators for Compressed Air Optimization

To collect data for improving these indicators, several measurement tools should be deployed:

- Flow meters: monitor real-time air consumption and detect abnormal variations.

- Pressure sensors: measure pressure at different network points to optimize settings and identify overpressure zones.

- Energy consumption analyzers: track compressor energy use to detect the most power-hungry systems and diagnose anomalies.

- Supervision software: these tools centralize and analyze collected data, offering an overview and identifying areas for improvement-for example, DATIVE’s DAT’Power solution.

- Energy audits and periodic diagnostics: provide in-depth analysis of installations, identify energy losses, and recommend targeted improvements. Regular audits help maintain performance and adapt to evolving needs.

Contact us to optimize your compressed air system

How to Optimize Your Compressed Air System?

Several actions can help improve the energy efficiency of compressors:

- Heat recovery: compressors generate significant heat during operation. This heat can be reused to warm buildings or industrial fluids, reducing external energy needs.

- Leak reduction: regular inspections and fast leak repairs help minimize losses and improve overall system efficiency.

- Pressure setting adjustment: tuning pressure to optimal levels for each application helps reduce overconsumption and equipment stress.

- Compressor technology: variable-speed compressors adapt output to actual demand, improving energy efficiency compared to fixed-speed models.

- Network redesign: adjusting the network by adding backup compressors or segmenting circuits optimizes air distribution. Isolating zones during off-hours or dedicating compressors to specific lines can reduce losses.

- Predictive and proactive maintenance: monitoring compressor health helps prevent failures and maintain optimal performance.

Conclusion

Compressed air is an essential yet often underestimated energy carrier in global industrial performance analysis. Its hidden cost-buried within electricity bills-masks significant optimization potential. By tracking the right indicators, deploying smart instrumentation, and implementing targeted actions, it’s possible to significantly reduce energy consumption while ensuring process reliability.

Compressed air optimization is part of a broader energy transition strategy-supporting both industrial competitiveness and long-term sustainability.