Carlo Gavazzi Meters and Sensors × DAT’Power: the winning combination for energy management

Looking to control your energy consumption and costs while meeting regulatory requirements (CEE, ISO 50001, BACS Decree)? By combining Carlo Gavazzi sensors and meters, the Dupline fieldbus and the DAT’Power Energy Management System, you can turn your site data into clear dashboards, relevant alerts and actionable decisions, delivering a tangible return on investment.

Industrial context and requirements

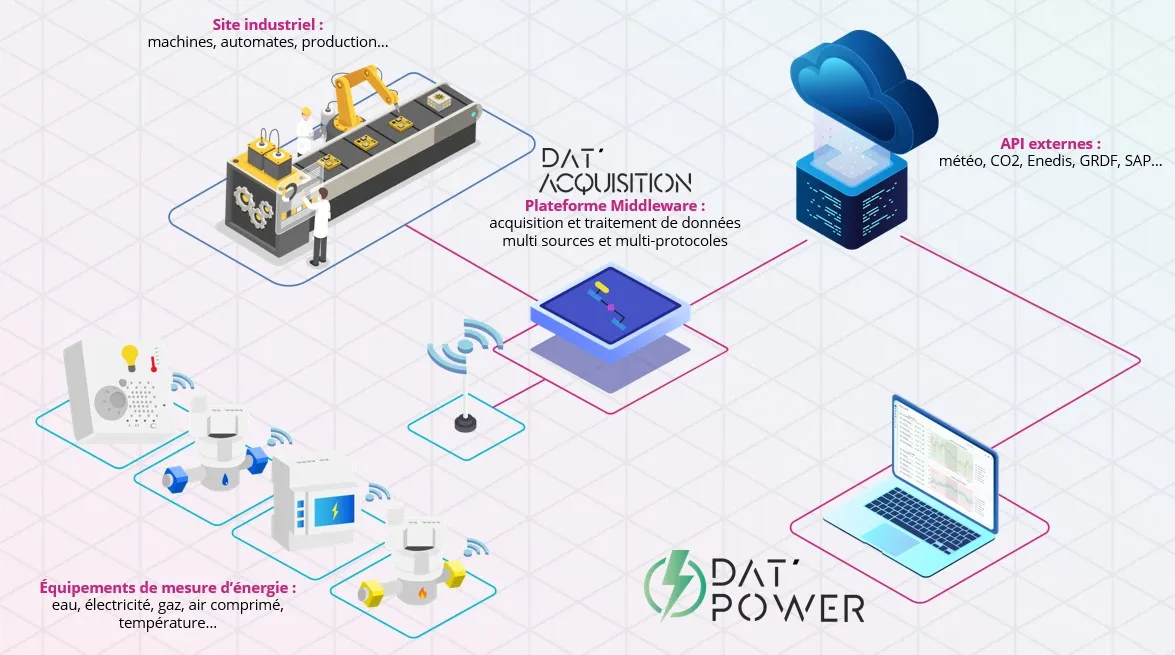

On an industrial site with multiple Significant Energy Uses or “SEUs” (electricity, compressed air, gas, heat), the priority is to quickly obtain reliable Energy Performance Indicators or “EnPIs” per SEU, detect deviations and translate them into €/day in order to prioritize maintenance actions. DATIVE’s approach is to leverage existing assets (meters, pulse outputs) and only complement them where it truly adds value, without replacing everything. In this context, the native integration of Carlo Gavazzi gateways into our Energy Management System or “EMS” DAT’Power simplifies connectivity and accelerates commissioning.

Even meters or sensors from different brands can be integrated without complexity, thanks to their exchange tables (Modbus RTU or TCP/IP) created during the initial configuration.

Confirms Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

Key indicators to monitor first: EnPIs per SEU, deviations converted into €/day, night baseload as a proxy for compressed air leakage rate.

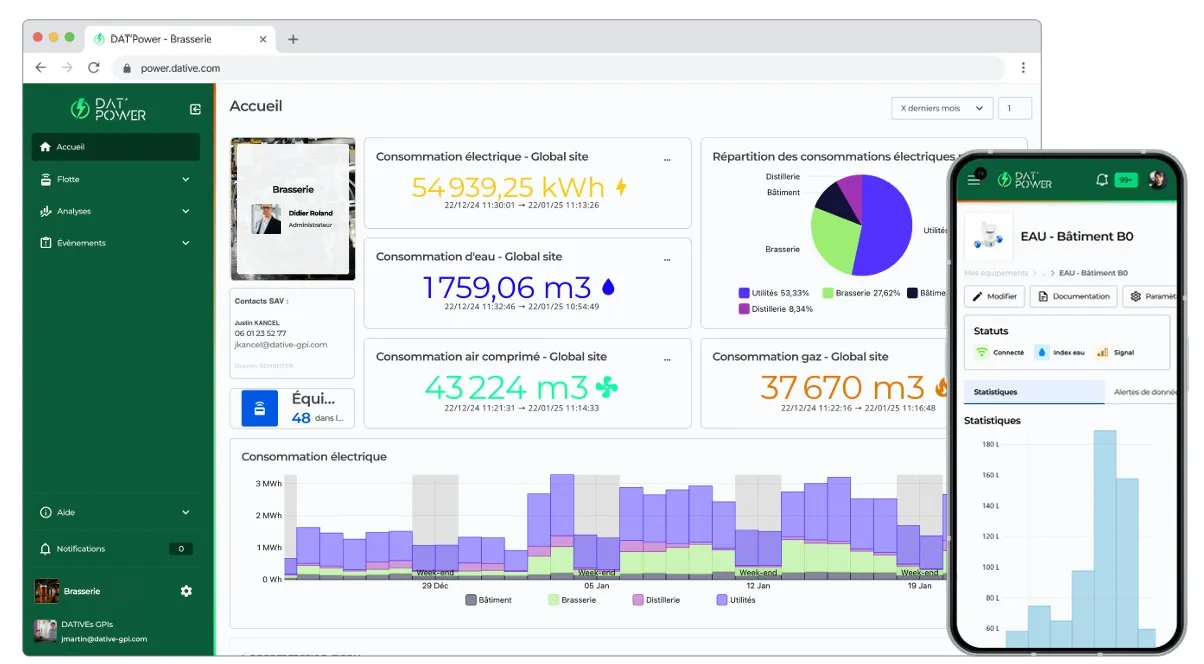

Proposed solution: DAT’Power, Carlo Gavazzi meters & sensors for enhanced energy management of your plant

Technical site visit and metering plan tailored to your industrial site

We carry out a site visit, define the metering plan and identify the highest value measurement points (electrical sub-metering, gas/water/heat pulse recovery, compressed air flow and pressure).

Our solution DAT’Power natively integrates your Carlo Gavazzi gateways, enabling rapid ingestion of existing communicating data. If you already operate a Carlo Gavazzi installed base, we complement it when necessary with compatible devices to extend measurement coverage.

Target EnPIs: kWh electricity/Nm³ for compressed air, m³ gas/kWh heat for boiler rooms, kWh electricity/production data from your ERP for electrical SEUs.

Contact our experts and schedule a technical visit on your site.

The main advantage of DAT’Power compared to basic supervision lies in the richness of information and flexibility: euro-based displays, advanced alerts, plant diagrams and point-level monitoring.

Explains Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

Financing study and budget validation with CEE incentives

Before any deployment, we verify your project’s eligibility for the CEE scheme IND-UT-134, dedicated to energy measurement and monitoring systems.

This step makes it possible to compare available incentive amounts with the overall investment cost (sensors, gateways, installation, software integration).

In practice, a customized estimate is produced: it compares your total CAPEX with potential incentive amounts in order to secure your investment decision and accelerate budget approval.

Get an estimate of your savings / ROI (including CEE IND-UT-134 incentives)

On-site implementation partnership: the strength of the Gérard Perrier Industrie Group

For instrumentation, electrical works and automation, we rely on the teams of the Gérard Perrier Industrie Group when on-site deployment is required, in coordination with your energy, maintenance and IT departments.

Deployment on your site: concrete steps

1 - Instrumentation and data acquisition for your site

We leverage the Carlo Gavazzi gateways already installed on your site to immediately feed data into DAT’Power. Depending on requirements, we add DIN-rail meters, pulse concentrators or suitable pressure/flow sensors. The Dupline fieldbus simplifies wiring in hard-to-access areas; a private LPWAN such as LoRaWAN covers remote zones. This “integrate first, complement later” strategy limits works and accelerates value creation.

Our meters and sensors combined with DAT’Power communicate directly via Modbus TCP/IP, or via 3G/4G modem if the customer does not wish to expose their network.

Comments Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

2 - Integration of your production and supervision data into DAT’Power

Integration of field data generally relies on standard Modbus TCP/IP or OPC UA connections.

This native compatibility makes it possible to automatically collect all energy measurements (electricity, gas, water, compressed air, heat) without specific developments. Exchange tables are clear, documented and adapted to each IT/OT environment, ensuring smooth integration into your existing supervision systems.

If you already use a centralized tool (SCADA, BMS, EMS, ERP, Power BI…), DAT’Power acts as an energy analytics layer. Data flows can be imported via files or APIs in order to link production indicators with actual energy consumption.

Calculated EnPIs are then consistent and comparable across SEUs:

- kWh electricity / Nm³ for compressed air,

- m³ gas / kWh heat for boiler rooms,

- kWh electricity / production data for electrical SEUs.

Data can be visualized directly in DAT’Power or pushed to customer tools — for example Power BI — for full and clear visibility of energy consumption.

Explains Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

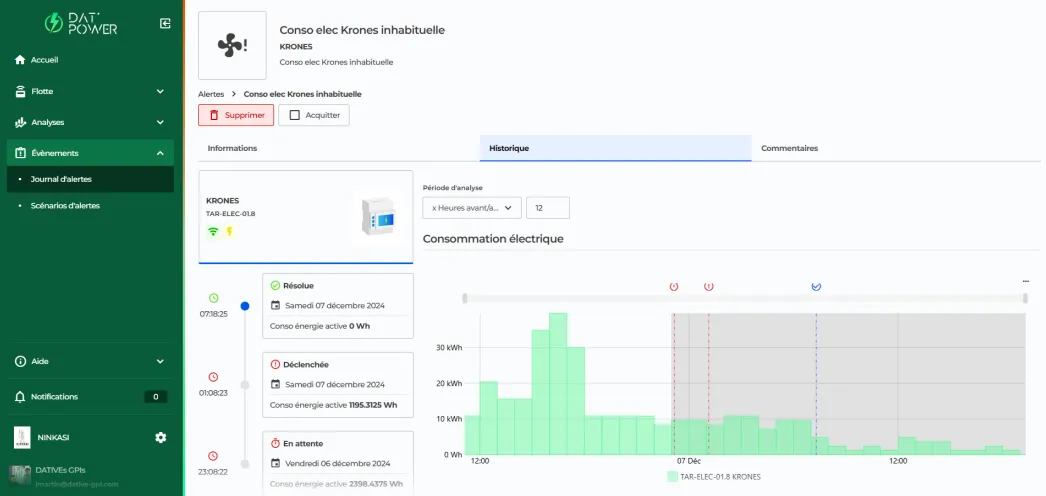

3 - Configuration of your customized dashboards

Once data flows are integrated, dashboards are configured according to user profiles:

- Management: consolidated cost view, target tracking and automatic conversion of deviations into €/day.

- Energy teams: EnPI monitoring per SEU, deviation and baseload detection, multi-energy visualization.

- Maintenance: access to histories, statuses, alarms and intervention prioritization.

Alert thresholds and monitoring time windows are adapted to your production schedules (day/night, weekdays/weekends).

Each view is customizable to enable reactive and shared management of deviations, while remaining readable for all site stakeholders.

4 - Training and change management support

Deployment concludes with a functional acceptance phase conducted SEU by SEU: verification of measurement points, alert testing, validation of EnPI calculations and data consistency. Key users (energy, maintenance, production) are then trained to read and interpret indicators, manage thresholds and update the metering plan.

These training sessions ensure long-term adoption and enable your teams to monitor energy performance over time without technical dependency.

Results and benefits you can expect

Once your DAT’Power platform is deployed, you benefit from a clear and consolidated view per SEU and per process, enabling immediate identification of deviations and their economic impact.

The compressed air baseload, often previously invisible, becomes a monitored indicator expressed in €/day. Energy deviations are detected earlier, investment decisions become faster and better substantiated.

DAT’Power also facilitates compliance with ISO 50001 initiatives, energy sobriety plans and CEE reporting. Gains are reflected in EnPI stabilization, cost reduction and improved coordination between energy, maintenance and production teams.

Contact our teams and obtain a precise ROI estimate

The main advantage of DAT’Power compared to basic supervision lies in the richness of information and flexibility: euro-based displays, advanced alerts, detailed plant diagrams and point-level consumption tracking.

Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

You can also read the 9 benefits of IIoT for industrial energy management.

Future developments and next steps for your plant

Control and automation of your industrial site

Beyond energy monitoring, DAT’Power can control simple loads such as lighting, ventilation or auxiliary machines thanks to its integrated dry contacts and configurable scenarios (occupancy, schedules, temperature conditions, etc.).

This makes it possible to build a lightweight BMS, perfectly complementary to existing hypervision, without additional complexity.

Integrating the Dupline fieldbus over several kilometers is simple and scalable. It enables adding I/O or automating certain programmable functions for data collection (BMS) and building automation according to customer needs.

Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

Your platform is therefore a scalable tool: initially focused on measurement and analysis, then progressively opening up to control and automation — naturally leading towards our industrial hypervision platform DAT’Process.

Predictive maintenance for your installations with DAT’Process

The logical next step after energy monitoring is predictive maintenance. By connecting DAT’Process to DAT’Power, teams can correlate load / no-load states, temperatures, vibrations and pressures on critical equipment (compressors, AHUs, heat pumps…).

This approach enables earlier detection of mechanical deviations, better planning of interventions and avoidance of costly shutdowns.

Discover how DAT’Process can improve the reliability of your equipment.

Conclusion

DAT’Power does more than collect data: it transforms it into a true industrial management tool, capable of aligning energy, maintenance and production teams around shared, actionable indicators.

The platform is suited to multiple use cases: energy via two Modbus RTU COM ports, DALI-2 lighting, machine activation, building management, water and gas consumption via the Dupline fieldbus. Deployment is fast and modular, zone by zone or by information type.

Explains Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

The combination of Carlo Gavazzi gateways and DAT’Power enables you to capitalize on existing assets, integrate data rapidly and progressively extend supervision.

Your project is delivered with comprehensive support from DATIVE teams, ensuring that energy supervision precisely meets the operational and financial needs of each site.

Their added value is clear: DAT’Power does not merely collect data. It transforms this information into a simple, efficient and scalable tool to optimize consumption and secure production.

States Frédéric Barberousse, Distribution Manager France & South-East Region, Carlo Gavazzi

To benefit from our expertise and deploy your own energy management system, contact our energy experts and take the first step toward tangible savings and concrete actions.