Deploying an Energy Management System on an Upper-Tier SEVESO Site: DAT’Power Client Case 2025

Anonymized 2025 case study: how we deployed DAT’Power on an upper-tier SEVESO site, in controlled phases, to balance HSE, cybersecurity, production continuity and measurable savings.

Introduction

Deploying an energy management system on an upper-tier SEVESO site—without disrupting production and while complying with HSE and cybersecurity constraints—requires a dedicated approach.

In this anonymized client case, we outline the client context (ATEX zones, confined spaces, work at height, POI/PPI, DREAL/SDIS audits, OT/IT segmentation) and our response. Our strength: a safe, measurable and repeatable deployment on your sensitive units.

Context and Constraints on an Upper-Tier SEVESO Site

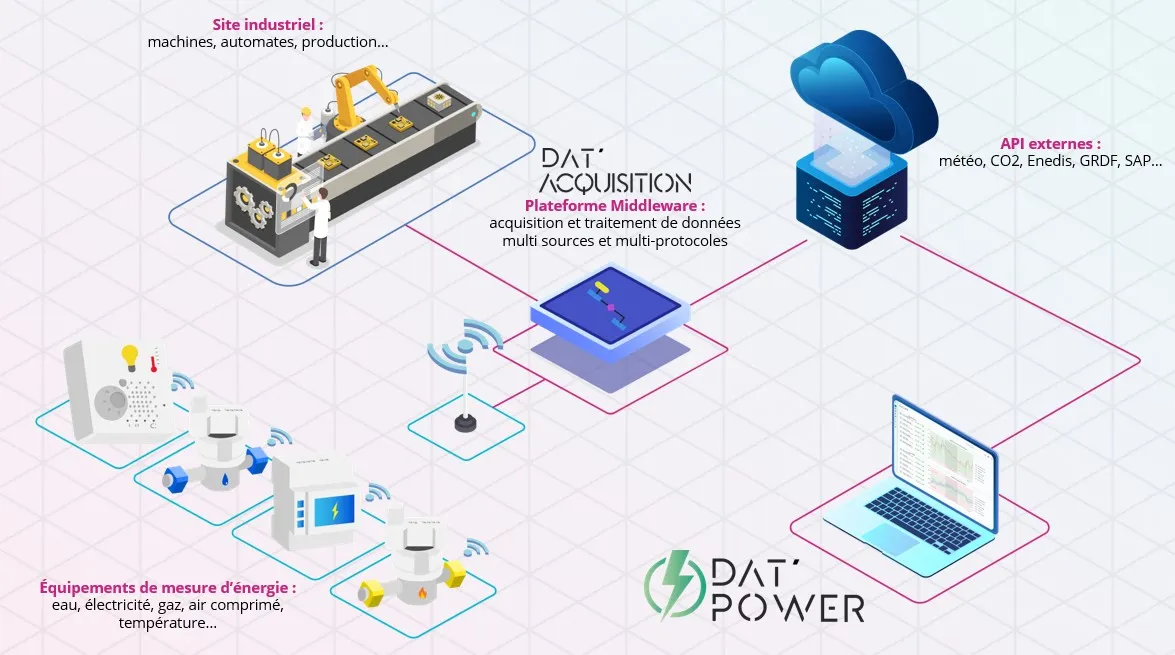

In this 2025 REX (retour d’expérience) on an upper-tier SEVESO site in the Lyon area, our DATIVE energy-optimization experts delivered: a metering plan, instrumentation, secure OT/IT integration, DAT’Power dashboards, acceptance and measured results. The project ran in three progressive phases to deliver quickly, reduce risk and structure a complex technical rollout:

- Phase 1 — Operational Foundation: targeted metering plan on critical ESUs (energy significant uses), reliable data collection, cybersecurity architecture, role-based dashboards, alerts and first KPIs (EnPI, baseload, €/day).

- Phase 2 — Extensions & Control: additional points, energy control scenarios (simple loads outside ATEX), advanced reporting and runbooks.

- Phase 3 — Predictive & Industrialization: DAT’Process (vibrations, temperature, loaded/idle states), multi-site standardization, governance and continuous improvement.

Regulations and HSE: Analyzing Client Obligations and Procedures

We started with an HSE-first framing: POI/PPI (Plan d’Opération Interne / Plan Particulier d’Intervention), permits, isolations/lockout, safety induction and coordination with planned outages. Concretely: go/no-go milestones, short production-compatible windows, pre/post checklists, and a shared log ready for audits.

On site, we worked with HSE and the shops: daily brief, controlled purging before tie-in, and repressurization under HSE supervision.

Result: zero incidents, zero unplanned downtime, full traceability.

You can also contact our experts to frame your project in sensitive environments.

Deployment Constraints for Meters and Sensors in a Critical Ecosystem

ATEX zones (equipment/methods), confined spaces (ventilation, gas detector, buddy system, lone-worker protection), work at height (lifelines, lifting), and hazardous substances: we selected suitable equipment for each zone, defined installation methods by class, systematically monitored the atmosphere and cordoned off each work area.

The installation was rehearsed “dry” beforehand; IP/IK checks and labeling were documented.

Deliverables: ATEX/height/confined-space dossier, post-installation checklist, signed logbook.

Managing Industrial Cybersecurity

Client requirements: no holes in OT, compliance with IEC 62443 / NIS2, logging, hardening, and MFA for remote access. We deployed least-privilege technical accounts, centralized logging, and a change-review process.

DATIVE has a dedicated industrial cybersecurity practice, to deliver the appropriate cyber posture for each client’s environment and business.

For remote access on this SEVESO project, we implemented a secure remote-maintenance gateway with an encrypted tunnel, multi-factor authentication and centralized session management. The exchange table (protocols, polling rates, units) was validated with IT; flow tests and a rollback procedure were executed before go-live.

Deliverables: zone/flow diagram, signed flow matrix, logs, cyber acceptance report.

Read our article on the NIS2 Directive to learn more about cybersecurity in Europe.

Organization and Operations (Audits, Continuity, Communication)

We aligned with shop/shift schedules, set go/no-go milestones, worked in micro-windows and verified the return to service. Day to day: shared log, coordination stand-ups, restart checks (measurements, sensors, cable trays, protections), and a weekly summary to the project committee.

Deployment on Our Client’s Industrial Site: REX 2025

Metering Plan & Targeted Instrumentation

We instrumented where it matters: ESUs for electricity / compressed air / gas / heat. Electrical sub-metering (AHUs, heat pumps, shops), gas boiler pulse inputs (m³), thermal energy meters, and compressed-air flow and pressure.

We use harmonized unit references (kWhelec/Nm³ for air, gas m³/heat kWh for the boiler house) to ensure consistent, comparable figures.

Book a session with our experts to validate your ESU list and metering plan.

Supervision/ERP Integration and Production Data

On the IT/OT side, we used Modbus TCP/IP and OPC UA depending on scope, and set up CSV exports via an ETL whenever a full application integration wasn’t needed.

The exchange table (addresses, units, polling rates) and quality checks (plausibility, interpolation for gaps) safeguarded the EnPI calculations.

At DATIVE, we handle virtually all industrial communication protocols, enabling multi-brand, multi-protocol integration of your existing assets.

Role-Based Industrial Energy Control Dashboards and Actionable Alerts (DAT’Power)

We configured Executive, Energy and Maintenance views so each function gets a monitoring interface matched to its field needs.

- Executive: consolidated costs and energy trajectory to track site commitments and prioritize efficiency investments.

- Energy: EnPIs by ESU, drifts expressed in €/day and night baseloads to expose hidden losses and adjust setpoints.

- Maintenance: automatic alerts, compressor idle time tracking, and intervention prioritization to curb consumption from technical drifts.

Rule example: if the compressed-air baseload exceeds X kWh for Y hours, open a ticket and notify team Z.

We finalized this phase with ESU-by-ESU acceptance, user training and go-live.

Request a demo of DAT’Power, tailored to your roles and industrial environment.

What Results and Tangible Benefits for This SEVESO Site After Implementing Its Energy Management Solution

Indicators, Quick Wins and Compliance

Visibility on EnPI by ESU and €/day alerts enabled rapid drift remediation and baseload reductions identified at night and weekends. The work achieved zero incidents with audit-ready traceability (DREAL/SDIS).

These first indicators confirm both the relevance of the deployment and the robustness of the methodology.

KPIs tracked: EnPI before/after, kWh → €/day → €/month by tariff periods, rate of relevant alerts, reaction time.

Example: compressed-air baseload detected then corrected, with an immediate drop in €/day.

Get an estimate of savings and ROI for your industrial site.

Roadmap and Next Steps for This Upper-Tier SEVESO Manufacturer

Moving from Monitoring to Active Energy Control of the Process

After securing supervision and consumption analysis, the client is preparing active energy control of certain assets. The goal is not only to measure, but to act automatically on selected equipment to optimize runtime in real time.

First, scenarios will target simple loads outside ATEX (lighting, ventilation, pumps) to cut unnecessary consumption during off-peak periods. These actions will follow a SEVESO-appropriate change-governance: impact analysis, rollback plan, and acceptance sign-off.

A limited pilot will validate reliability and safety before a progressive scale-up by zone, ensuring measurable, well-controlled gains.

Predictive Maintenance with DAT’Process

Beyond monitoring and energy control, you can go further into global process control with DAT’Process.

This DATIVE-developed predictive-maintenance solution leverages field data (vibrations, temperatures, loaded/idle states, pressures, electrical consumption) to anticipate mechanical and energy drifts on critical equipment. As a logical extension of DAT’Power, it goes beyond measurement: correlate process and energy signals, predictively detect abnormal behavior and auto-trigger work orders in the CMMS.

Objectives: cut unplanned downtime, extend equipment lifespan and stabilize EnPIs over time.

DAT’Process also goes further: quality tracking and scrap reduction, knowledge capture, and improved collaboration/knowledge-sharing, etc.

Discover DAT’Process and its use cases in sensitive environments or check out our e-book on predictive maintenance with DIMO

Conclusion

This project showcases our ability to work on high-requirement sites — upper-tier SEVESO — while reconciling safety, performance and innovation. Thanks to a phased methodology, our teams deployed a robust DAT’Power foundation, progressively expanded energy coverage and paved the way for intelligent control of installations.

Beyond monitoring, this approach places data at the heart of industrial decisions: measure, understand, act, then predict. With DAT’Process, this continues into predictive maintenance to anticipate drifts, improve reliability and ensure production continuity.

A successful energy transition relies as much on method and team enablement as on technology.

Want to know how to apply this approach to your own site? Contact DATIVE’s experts to build your metering plan, energy-control strategy and future predictive bricks.