Pharmaceutical industry: OT cybersecurity facing public health and performance challenges

In the pharmaceutical sector, industrial cybersecurity is no longer just about protecting sensitive data. It now underpins the reliability of every medicine produced, the continuity of production, and the trust placed by health authorities. Faced with interconnected OT infrastructures, strict regulatory obligations and critical public health stakes, DATIVE supports manufacturers in securing their critical environments and sustainably improving their operational performance.

OT cybersecurity challenges in the pharmaceutical industry

In the pharmaceutical industry, cybersecurity is not just a regulatory requirement: it has become a vital factor for performance and trust. Industrial systems, interconnected at every stage of the process, support the continuous production of medicines, where the slightest alteration can have major public health consequences.

Between quality requirements, production pressure and compliance obligations, pharmaceutical OT environments demand constant vigilance and full control of digital risks.

Drug manufacturing: every second counts

In a pharmaceutical environment, precision and continuity are non-negotiable. A filling line stoppage or a communication loss between a PLC and the SCADA system can desynchronise the whole production chain. Equipment is interconnected, flows must remain stable, and even minor network latency can disrupt batch traceability or block a validation step.

At DATIVE, we regularly observe this total interdependence between industrial performance and OT system availability. In a sterile area, a simple communication loss is enough to halt production. Each minute of downtime has an immediate impact on productivity, quality and sometimes on regulatory compliance.

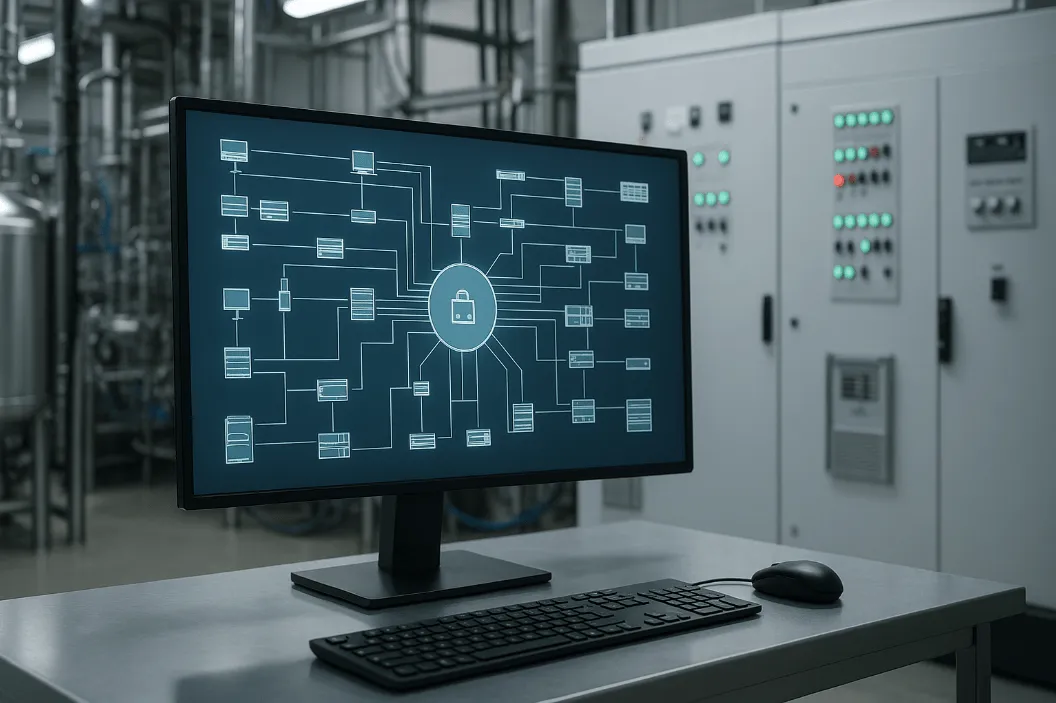

OT cybersecurity is therefore not just about deploying barriers. Its purpose is to ensure that exchanges between PLCs, SCADA servers, MES and quality systems remain reliable, continuous and integral.

When cybersecurity becomes a public health issue

Pharmaceutical cybersecurity goes far beyond the industrial perimeter: it lies at the heart of public health. A cyber incident, whether accidental or malicious, can compromise drug quality, corrupt batch record data or undermine the integrity of an entire lot.

The risks are very real: cross-contamination, large-scale recalls, stock shortages… all events which, beyond their economic impact, can weaken the trust of patients and health authorities. By protecting control systems (SCADA, DCS, PLCs), we indirectly protect patients. And in this sector, trust is as essential a value as any quality protocol.

This is why OT cybersecurity is now seen as a link in the public health chain. It does not only protect infrastructures: it protects traceability, reliability and reputation.

Compliance and cybersecurity: a delicate balance

Quality and regulatory standards in the pharmaceutical sector

The pharmaceutical sector is one of the most heavily regulated in the world. Every item of data, every measurement, every action must be traceable, verifiable and validated.

The frameworks governing these requirements are numerous:

- Good Manufacturing Practices (GMP / BPF): the backbone of all pharmaceutical production,

- Computer System Validation (CSV, GAMP 5): ensuring that every system is qualified, validated and documented.

These frameworks do not explicitly address OT cybersecurity, but their need for full control of systems creates a natural convergence. Cybersecurity becomes the logical extension of quality: it is impossible to guarantee product integrity if the digital environment that produces it is not itself trustworthy.

How these requirements intersect with OT cybersecurity

The production of medicines, injectable products or single-dose formats requires validation and traceability. OT cybersecurity brings resilience, segmentation and risk management. These domains naturally converge.

A documented OT network segmentation addresses both GMP / BPF expectations and OT security objectives. Controlled remote access is part of both quality control and cybersecurity. Rigorous technical documentation is just as useful during an audit.

At DATIVE, we help pharmaceutical professionals turn these obligations into concrete actions: governance, hardening, supervision and validation of critical OT systems.

Request your cyber audit, the starting point for securing your industrial site.

What we see in the field

Recurring findings in pharmaceutical environments

Our engagements in the pharma sector often highlight recurring issues:

- An incomplete or poorly documented IT/OT segmentation, sometimes inherited from the site’s history.

- A limited patch management capability, as each update requires quality revalidation.

- Remote access with limited control, often managed directly by maintenance providers.

- And above all, a high level of obsolescence in industrial equipment: PLCs, SCADA servers, DCS systems sometimes more than ten years old.

These vulnerabilities are not purely technical: they reveal how difficult it is to reconcile availability, compliance and security.

Our DATIVE approach: acting without disrupting production

We know that in a pharmaceutical environment, every intervention must be invisible to production. This is why our cyber audits are based on a methodology that respects the process: on-site observation, passive traffic capture, out-of-band analysis and detailed mapping of communications.

We work hand in hand with quality, maintenance and IT teams to understand the dependencies between systems. This collaboration allows us to recommend realistic actions, aligned with regulatory constraints and validation cycles.

Our difference? We come from industry, for industry. Our engineers speak the language of production, understand automation logic and know where the real risks lie.

Before securing, we understand. Contact our cyber engineers.

Pharma-focused OT audits and diagnostics

We carry out a complete mapping of flows, interconnections and critical dependencies. We analyse performance, stability and latency of OT communications to identify weak spots: saturated switches, misconfigured gateways, unsynchronised redundant servers…

The objective? Provide a simple, actionable view of the site’s technical reality — an essential foundation before any security strategy.

Securing and continuously monitoring your production processes

Once the foundations are in place, the focus shifts to supervision. We integrate IT/OT correlation solutions capable of detecting network anomalies, access attempts or abnormal device behaviour. These tools do more than trigger alerts: they contextualise events to avoid information overload.

Privileged access, often overlooked, is also controlled: account management, session traceability, strong authentication and remote connection control. This continuous supervision framework turns cybersecurity into a daily management tool serving performance.

Compliance and long-term governance

Compliance is not an end state: it is an ongoing process. We support pharmaceutical sites in achieving compliance with IEC 62443, NIS2 and GMP requirements. This involves creating security policies adapted to OT environments, documenting configurations and clearly defining roles and responsibilities.

We help teams establish sustainable governance: system hardening, segmentation, redundancy, contingency planning. Each recommendation is realistic, measurable and embedded in day-to-day operations.

And because no framework is sustainable unless it is understood, DATIVE supports the increase in cyber maturity of pharmaceutical sites through training, skills transfer and long-term support.

Towards sustainable pharmaceutical cybersecurity

Cybersecurity as a pillar of quality and trust

In pharma, quality and cybersecurity are not opposed: they reinforce one another. Securing a process means preserving the integrity of the finished product. A reliable, controlled OT network ensures that production data faithfully reflects what happens in the field.

Cyber resilience therefore becomes an indicator of operational quality. A site capable of detecting, isolating and containing an incident preserves the continuity of its core mission: producing, in full confidence.

Building a sustainable security model

Cybersecurity is not a one-off project, but a continuous dynamic. Monitoring, documentation, recovery testing, dependency verification: everything must evolve in step with the site.

At DATIVE, we view security like Good Manufacturing Practices: a system of continuous improvement, auditable, traceable and focused on reliability. Every action taken today prepares tomorrow’s compliance and performance.

DATIVE, long-term partner of the pharmaceutical sector

We know that health industry players are not looking for short-lived providers, but for long-term partners. Our vision: cybersecurity integrated into performance and quality, not imposed as a constraint.

Our commitments are built around three pillars:

Would you like to assess or strengthen the cybersecurity of your pharmaceutical site? Contact our DATIVE teams.

Conclusion

OT cybersecurity in pharma goes beyond the technical perimeter: it is a matter of public health and trust.It embodies the guarantee that every medicine produced, every piece of data recorded and every batch released are protected, reliable and traceable.

DATIVE supports sector players in this silent transformation, where security and performance become one. Ultimately, securing a pharmaceutical plant means protecting far more than systems: it means protecting lives. Would you like to assess or strengthen the cybersecurity of your pharmaceutical site? Contact our DATIVE teams.