Energy Optimization of Steam Boilers: Practical Levers to Cut Your Industrial Costs

Steam boilers account for a major share of industrial energy consumption. How can you reduce their usage without compromising production reliability? This expert article highlights the key performance indicators to monitor, the right measurement methods, and concrete optimization levers, illustrated with real-world field feedback.

Introduction

Optimizing a steam boiler means sustainably reducing energy costs, lowering emissions, and ensuring reliable production. This guide details measurable benefits, key KPIs to track, appropriate measurement methods (field + supervision), and priority technical actions—enhanced with DATIVE’s field experience.

What benefits can you gain from improving the energy efficiency of your steam boilers?

Lower operating costs

Higher efficiency means less fuel is needed to produce the same amount of steam. For example, lowering flue gas temperature by just 20 °C can yield 1–2% annual gas savings. Installing an economizer or simply tuning combustion can quickly generate tens of thousands of euros in savings for a medium-sized boiler.

Indirect costs also decrease: less fresh water to heat thanks to condensate return, and fewer chemicals for water treatment. On some sites, reusing 70% of condensates has reduced water treatment costs by nearly 15%.

Improved environmental performance

Each efficiency point gained proportionally lowers CO₂ emissions from combustion. On a 10 t/h gas-fired boiler, adding an economizer can avoid several hundred tons of CO₂ emissions per year.

Condensate reuse also reduces potable water consumption and effluent discharge, supporting CSR objectives and simplifying environmental reporting (carbon footprint, ISO 50001).

Regulatory compliance

European and national frameworks require improvement actions and objective monitoring of energy performance. An instrumented boiler room with reliable indicators and regular reporting via our DAT’Power solution simplifies energy audits, multi-site consolidation, and the creation of deliverables requested by authorities or internal standards. The benefit is twofold: easier compliance and data-driven optimization levers.

Equipment protection and value preservation

Stable efficiency reflects a well-tuned and well-maintained boiler. Conversely, poor combustion causes fouling, premature wear, and unplanned shutdowns. Without a monitoring program, up to 30% of steam traps may fail after a few years. Implementing systematic maintenance reduces this rate to below 5%, resulting in higher availability and extended life of the boiler body and auxiliaries.

Access to funding programs

Instrumentation and energy monitoring of steam boiler rooms are covered by the CEE IND-UT-134 certificate (“System for measuring energy performance indicators”). This means a monitoring project such as DAT’Power is 100% eligible for the Energy Savings Certificates program.

This advantage greatly reduces—or even completely eliminates—the remaining cost for the operator.

During our on-site technical visit, we provide a precise estimate of mobilizable CEE incentives to secure project financing and accelerate decision-making.

Schedule a technical visit with a DATIVE expert

Key indicators to drive the energy optimization of your steam boilers

An optimization plan is only valuable if it relies on reliable measurements tracked over time. To effectively manage a steam boiler room, several energy performance indicators (EPIs) must be monitored regularly. They reveal gains, identify deviations, and help prioritize corrective actions.

Overall boiler efficiency

This is the basic indicator: it compares useful energy produced (steam) to energy consumed (fuel). Low efficiency typically indicates poor combustion tuning, a fouled economizer, or high flue gas temperature. Regular tracking detects hidden losses and verifies the effectiveness of corrective measures.

Blowdown rate

Blowdowns prevent impurity buildup in boiler water but carry away energy. A blowdown rate above 5% of steam production is a warning sign of significant heat loss. Monitoring feedwater conductivity allows fine-tuning of blowdowns to avoid unnecessary losses.

Steam pressure and temperature

Overheated or too-wet steam degrades process performance and equipment safety. Stable pressure and temperature reflect proper regulation and correct sizing of auxiliaries (deaerator, tank, safety valves).

Specific consumption per process

Expressing steam consumption in kg or tons of steam per production unit (ton of paper, m³ of product, etc.) is a powerful lever. It enables comparisons between workshops or machines and tracks energy efficiency relative to production volumes.

Radiation and insulation losses

Poorly insulated boilers or degraded networks cause continuous losses. Monitoring surface temperature at key points (valves, flanges, collectors) highlights insulation defects. These losses are often underestimated, yet represent tens of MWh per year on a large site.

CO₂ emissions monitoring

Linking fuel consumption to official emission factors directly tracks the carbon footprint of steam production.

This indicator is increasingly required for environmental assessments and CSR reporting.

Importance of continuous monitoring

Spot checks are not enough: continuous monitoring is essential to quickly identify deviations (e.g., blocked trap, fouled economizer, efficiency drop). Indicators must be stored, consolidated, and analyzed regularly for fact-based decision-making.

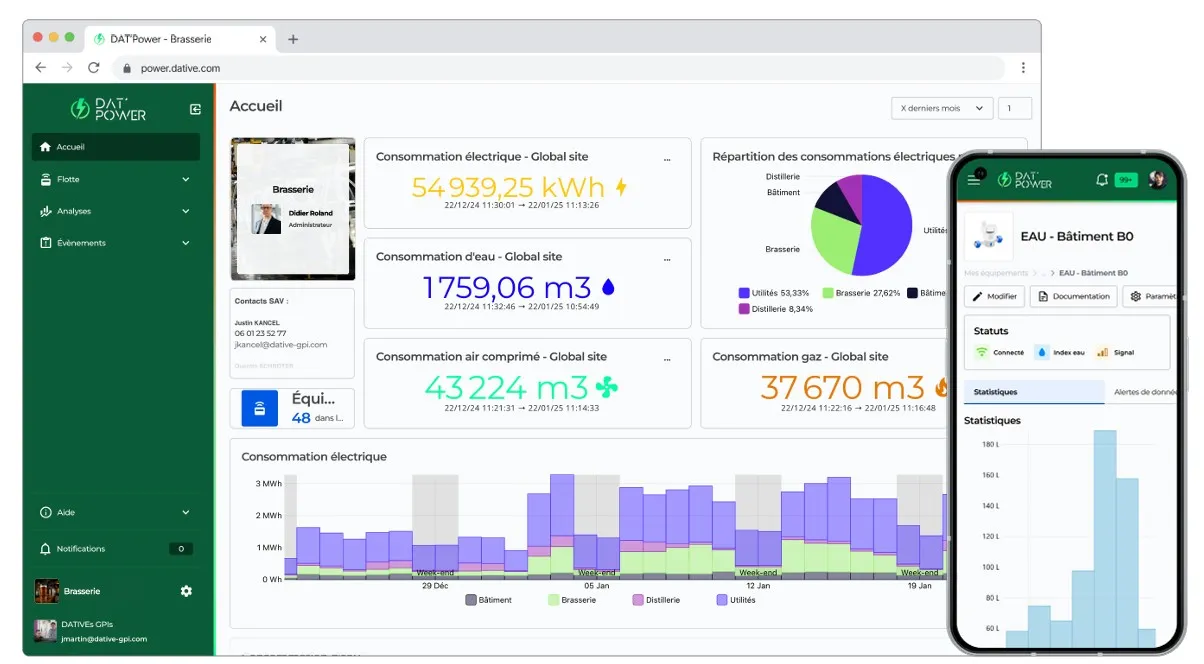

With our DAT’Power solution, create custom dashboards to track these indicators in real time and detect performance deviations as soon as they appear.

How to obtain these indicators to effectively measure your steam boiler performance

Measurement methods (sensors, analyzers, audits, etc.)

At DATIVE, we recommend tailored instrumentation for each boiler room to obtain reliable, actionable data:

- Water meters to monitor make-up water and quantify actual consumption.

- Steam flowmeters: prioritize vortex models for robustness, or swirl technology when hydraulic constraints require it.

- Non-intrusive inline flowmeters for measurements on critical pipelines without interrupting production.

- Thermal energy meters to compare gas kWh consumed, tons of steam produced, and calories in returned condensates.

- Temperature and pressure sensors to convert measured flows to normalized m³ and ensure accurate performance calculations.

These instruments form the basis for calculating overall efficiency, managing blowdowns, monitoring condensate returns, and establishing energy performance indicators recognized in standards (ISO 50001, CEE).

Centralize and store data with DAT’Power hypervision

Having sensors is a first step, but value comes when data is aggregated and stored. A hypervision platform like DAT’Power centralizes information and makes it readable via dashboards: overall efficiency, specific consumption per workshop, condensate return rate, CO₂ emissions. This consolidation enables site-to-site comparisons and prioritization of actions based on potential gains.

Leverage predictive analytics

With continuous data, predictive logic becomes possible. A blocked steam trap shows up as a temperature drift; a fouled economizer as a rise in flue gas temperature; poor combustion as excess O₂. Detecting these weak signals early allows intervention before they cause failures or overconsumption.

If you’re interested in predictive analysis, check out our full e-book “Practical Guide to Predictive Maintenance” in partnership with Dimo Maint.

Automate reporting and alerts for fast action

Automated reporting saves time and ensures compliance. Instead of manually compiling readings, data is transformed into standardized reports (ISO 50001, energy audits, carbon footprint). Configurable alerts (e.g., efficiency drop, excessive blowdown) guarantee immediate on-site responsiveness.

Case study: how DATIVE supports DS Smith in optimizing its steam boilers across France

At DS Smith plants, progressive deployment of DAT’Power instrumentation enables real-time tracking of indicators such as efficiency, flue gas temperature, and condensate return rate. The result: consistent visibility across sites, earlier detection of deviations, and action plans prioritized based on factual data.

How to optimize industrial steam boilers

Automation and blowdown reduction

- Install a conductivity sensor on the feed tank or boiler drum to automatically trigger blowdowns.

- Check conductivity setpoint: too low = energy losses, too high = scaling risk.

- Add a flash tank to cool and depressurize blowdowns before discharge, recovering energy as flash steam to preheat a water tank.

Action step: check the current blowdown rate (% of steam produced) and compare it with the recommended target (< 5%).

Heat and condensate recovery

- Trace the condensate network to identify sections where condensates are discharged instead of recovered.

- Install or replace faulty steam traps: up to 30% may be defective without maintenance.

- Add a buffer tank or deaerator to centralize and return condensates to the boiler.

- Combine condensate recovery with an economizer to preheat feedwater upstream.

Action step: record the current condensate return rate (kg/h or % of steam produced) and identify workshops or lines where condensates are lost.

Continuous performance monitoring and analysis

- Install a vortex flowmeter on the main steam line to measure actual production.

- Monitor flue gas temperature downstream of the economizer: a +20 °C deviation may signal fouling or poor burner adjustment.

- Set up automatic alerts (efficiency < 85%, blowdown > 5%, drop in condensate return rate).

- Store data to compare month-to-month and validate savings.

Action step: check the flue gas temperature/setpoint and compare it to the “new” value provided by the manufacturer.

Use of Energy Savings Certificates (CEE)

The IND-UT-134 certificate specifically covers steam boiler rooms ≤ 10 MW. It funds the implementation of a complete energy measurement and monitoring system. At DATIVE, we deploy CEE-funded projects ranging from €10,000 to €50,000, significantly reducing the remaining cost. During the technical visit, our teams deliver the following:

- a detailed energy metering plan eligible for CEE (NF EN 17267 standard)

- a precise estimate of mobilizable CEE incentives

- the energy specifications required to carry out the project

Action step: schedule a technical visit with our DATIVE energy experts to assess eligibility and quantify mobilizable CEE incentives

Conclusion

Energy optimization of a steam boiler is not about a single action but a holistic approach: adjust blowdowns, recover heat and condensates, instrument key measurement points, and continuously monitor indicators. Each lever contributes to savings; combined, they enhance the overall performance of the boiler room.

At DATIVE, we support industrials starting from the field: a technical visit to understand your installation, a tailored metering plan, and a clear estimate of available CEE incentives. This ensures rapid progress with a secure return on investment.

Interested in seeing what this could look like for your site? Contact a DATIVE expert to schedule an on-site visit or an initial video consultation.