Industrial Steam Boilers: Operation, Applications, and Efficiency Levers

Industrial steam remains a cornerstone of many manufacturing processes. How does a steam boiler work? What are its main uses, and where are the key levers to reduce energy consumption? This article provides a clear, accessible overview of steam boiler operations and practical paths for optimization.

What Is Steam Used for in Industry?

Steam is primarily an energy carrier. It transports a large amount of heat, can be easily distributed across workshops, and provides stable and uniform temperatures for processes. This combination explains its longevity: despite competition from other technologies, it remains an industrial standard.

Its uses are very concrete:

- In the food industry, steam is used to cook food, sterilize products, or perform clean-in-place operations (CIP/SIP).

- In paper and cardboard production, it dries sheets as they exit the machine—a highly energy-intensive stage.

- In chemical and pharmaceutical plants, it is used in autoclaves to ensure equipment and product sterility.

- In the textile industry, it facilitates certain heat treatments and fiber shaping.

What makes steam so effective is its versatility. It can heat a heat exchanger, power a dryer, or disinfect equipment. It reaches high temperatures quickly, but is equally efficient for gentle, controlled heat maintenance.

Steam is therefore a universal industrial tool: a single energy vector capable of meeting very different needs, with an energy efficiency that is hard to match with other fluids.

A Quick Look at a Steam Boiler Room

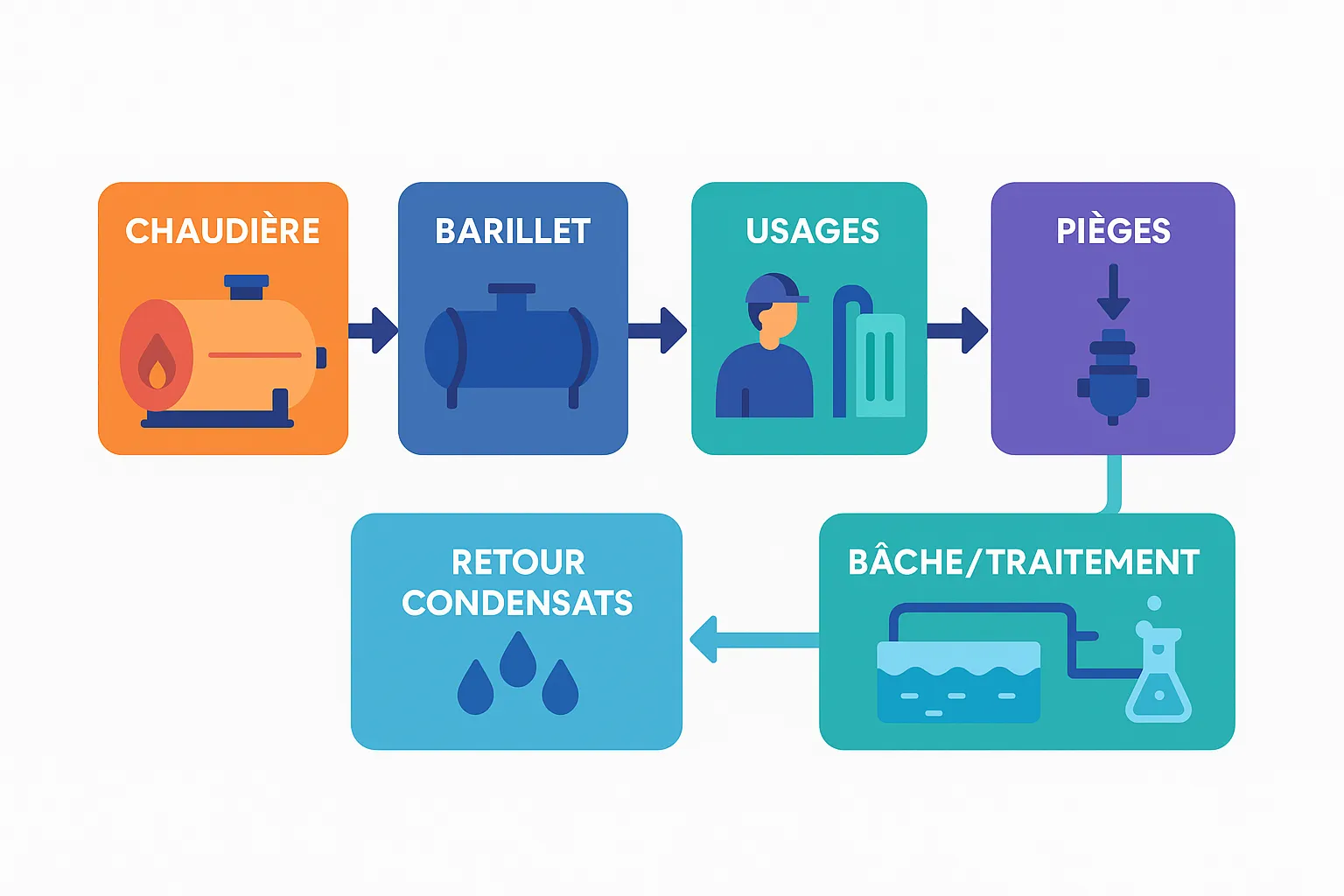

A steam boiler is not a stand-alone piece of equipment: it operates within a complete system called the boiler room. Understanding this system is essential to identify where energy losses occur and where efficiency gains can be achieved.

A typical boiler room includes several key components:

- The boiler and burner: the heart of the system, where the fuel’s energy (gas, oil, biomass) is converted into heat. Often combined with an economizer to recover heat from flue gases to preheat the feedwater.

- The steam drum (or collector): regulates the steam produced and distributes it to the various workshops.

- Process uses: heat exchangers, dryers, autoclaves, cooking or sterilization lines. This is where steam transfers its energy and condenses.

- Steam traps and the condensate network: recover condensate water while preventing live steam from escaping unnecessarily.

- Condensate return to the feed tank or deaerator: a key step to reuse already hot, treated water, reducing the need for fresh water, chemicals, and fuel.

- Water treatment and blowdown: properly treated water prevents deposits and corrosion; blowdown removes impurities and passes through a flash tank for safety.

The ideal steam boiler room operates as a closed loop where production, use, and return remain balanced. The most effective energy-saving levers lie in the exchanges between these blocks—especially condensate return and the economizer.

How Does a Steam Boiler Work?

A steam boiler works on a simple principle: water is heated and turned into steam, which is then used as an energy carrier before being returned to the boiler as condensate. Behind this basic idea, however, is a continuous sequence of operations running 24/7 in industrial plants.

It all starts in the burner, where the energy of a fuel (usually natural gas) is released through combustion and transferred to the water inside the boiler shell. As the temperature rises, the water turns into steam. This steam is stored in the steam drum and routed to workshops as needed.

During these uses, the steam releases its energy as it condenses back into hot water—known as condensate. Instead of being discarded, the condensate is collected and returned to the boiler room. Before reinjection, it typically passes through a feed tank or deaerator to remove dissolved gases and stabilize its temperature. Fresh treated water is added to compensate for losses, and the cycle continues.

This closed-loop principle distinguishes a steam boiler from a hot-water boiler. In the latter, water is simply heated and circulated in closed loops (district heating, workshop heating) without changing state. A steam boiler, by contrast, uses the liquid → steam → liquid phase change as the engine for thermal transfer. This makes steam more complex to manage but far more versatile for industrial processes.

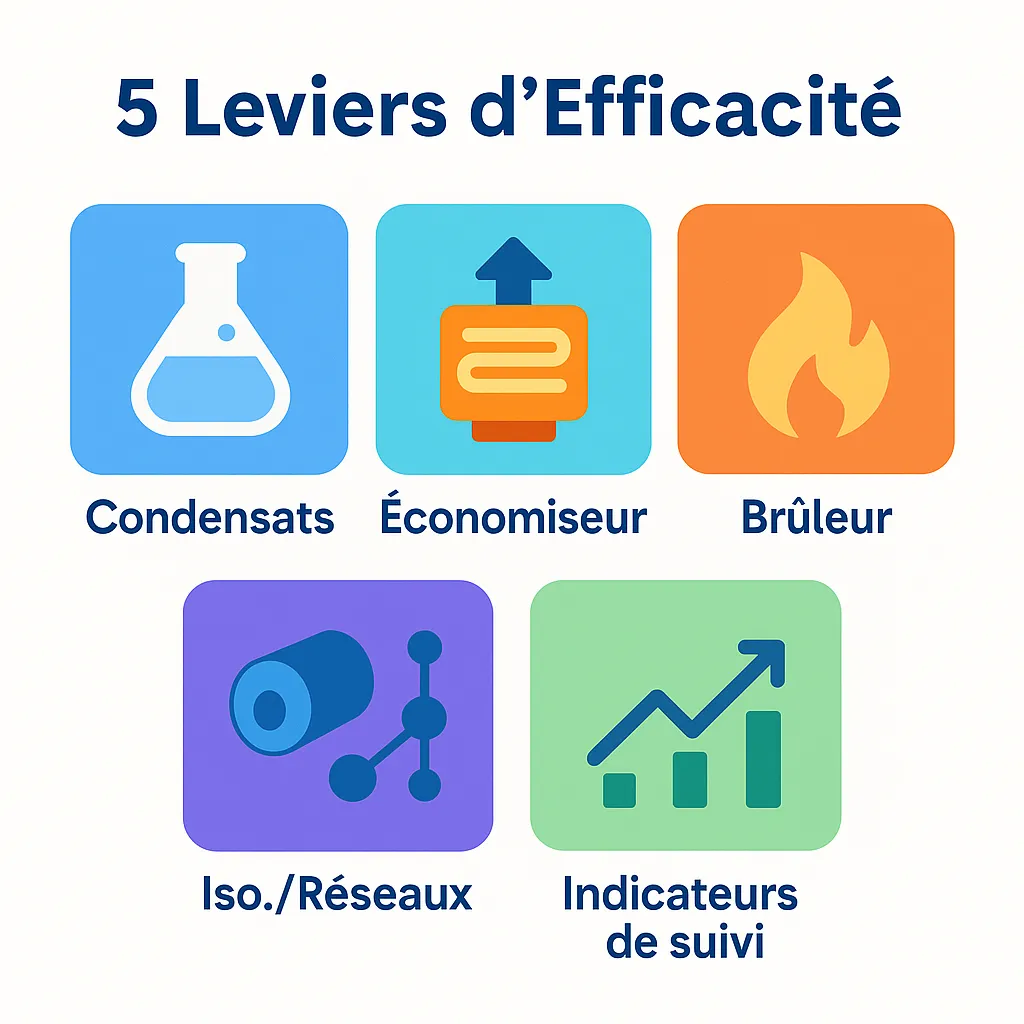

Simple Ways to Reduce Consumption

A steam boiler room is not fixed: its performance depends on how it is operated and maintained. Before considering heavy investments, several relatively accessible actions can already reduce fuel consumption and improve reliability.

The condensate return is often the first lever. Each kilogram of condensate still contains significant heat and has already been chemically treated to prevent corrosion and scaling. Reusing condensate therefore reduces fresh water needs, chemical consumption, and fuel requirements. In some plants, simply improving pump-back or steam trap management can boost cycle efficiency by 10–20%.

Another major lever is the flue-gas economizer. By recovering heat from combustion gases to preheat the feedwater, it prevents valuable calories from being lost up the stack. Gains of 4 to 6 efficiency points (based on the lower heating value) are common, provided the exchanger is kept clean and properly sized for flue-gas and water flow.

Combustion quality also plays a critical role. Excess air or a poorly maintained burner results in hotter flue gases and energy losses. Regular monitoring of O₂ content in flue gases, combined with proper tuning, helps optimize combustion and reduce fuel consumption.

Finally, don’t overlook the distribution network. An uninsulated valve or a stuck steam trap may seem minor, but multiplied across dozens of points, it causes continuous losses. Insulating sensitive sections, periodically checking traps, and monitoring blowdowns are simple actions often paid back within months.

Safety and Regulatory Framework

Steam boilers are not like other equipment. They operate under pressure and at high temperatures, requiring a strict regulatory framework to protect operators and ensure installation reliability.

In Europe, the market placement of boilers is governed by the Pressure Equipment Directive (PED 2014/68/EU). In France, their operation is subject to the Order of November 20, 2017, which defines monitoring and inspection rules. In practice, each boiler must be regularly inspected by approved organizations according to a defined inspection program, and safety devices such as relief valves must be installed and periodically tested.

These regulatory obligations are mandatory and directly concern the plant operator. Compliance ensures both personnel safety and production continuity.

-> Important: DATIVE does not handle regulatory safety or boiler compliance. Our role focuses exclusively on energy measurement, consumption management, and decision support. Inspections and compliance remain the responsibility of control agencies and boiler manufacturers.

How DATIVE Helps Improve Your Steam Performance

Improving steam boiler performance starts with better monitoring and reliable data. You cannot act effectively without knowing where losses occur or without dependable indicators to track progress. Instrumentation and real-time monitoring make this possible.

At DATIVE, we act on two levels:

- Technical audit and metering plan: on-site, our teams identify the most relevant measurement points to cover the entire steam-condensate cycle. The goal is a clear view of production, consumption, and major losses.

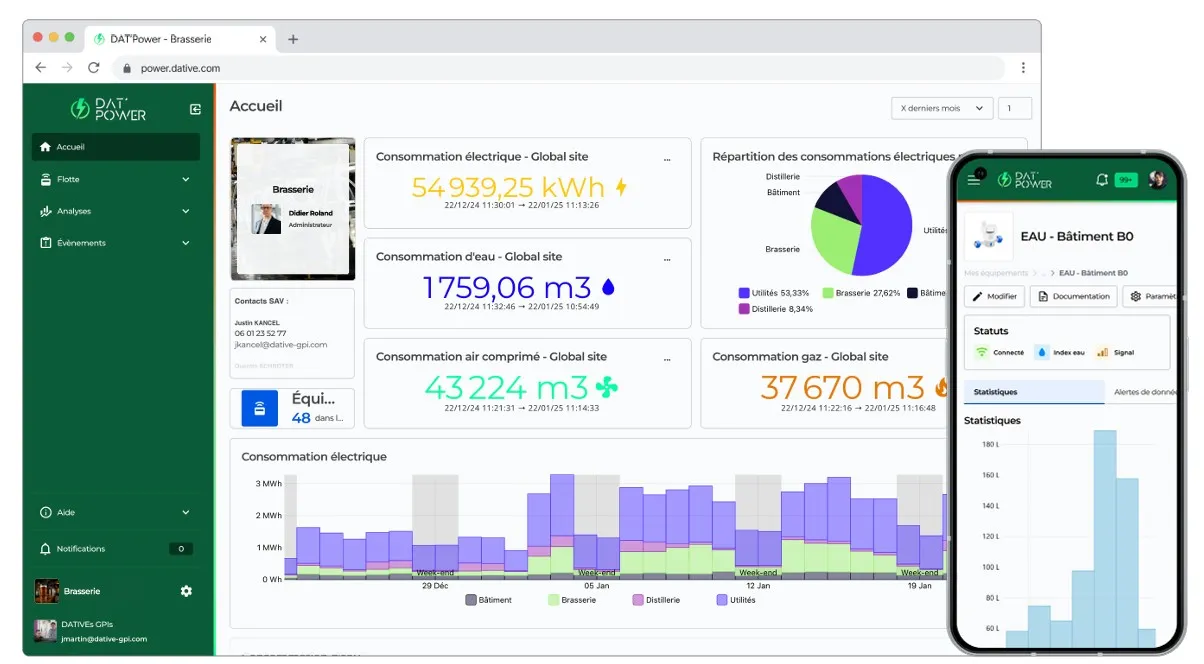

- DAT’Power: our platform centralizes data and provides key indicators such as boiler apparent efficiency, flue-gas temperature, condensate return rate, or feed tank conductivity. Dashboards track boiler room efficiency in real time and quickly detect any drift.

This pragmatic approach has already been deployed in many plants, particularly in the paper industry where steam consumption is a major cost. Client feedback shows that with proper instrumentation it is possible to quantify losses precisely, prioritize actions (condensate return, economizer, combustion tuning), and document gains for ISO 50001 certification or energy-savings certificate (CEE) applications.

Conclusion

Steam remains a cornerstone of industry, but its efficiency depends heavily on how the boiler room is operated. Condensate return, heat recovery, trap maintenance, and indicator monitoring are all simple actions that generate measurable gains.

Want to identify your optimization potential? Contact a DATIVE expert for a pragmatic measurement plan and a DAT’Power dashboard tailored to your boiler room.

FAQ – Industrial Steam Boilers

Can a Boiler Optimization Project Be Funded?

Yes. Depending on your boiler’s rated capacity, it may be possible to finance all or part of a project through Energy Savings Certificates (CEE). A DAT’Power deployment is 100% eligible for this program, significantly reducing the remaining cost.

What’s the Difference Between a Fire-Tube Boiler and a Water-Tube Boiler?

Fire-tube boilers pass hot gases through tubes surrounded by water. They are simple, robust, and widely used. Water-tube boilers circulate water through tubes heated by flue gases and are better suited to high pressures and large steam flows.

Why Is Condensate Recovery So Important?

Because condensate arrives already hot and treated. Reinjecting it reduces water, chemical, and fuel consumption while stabilizing boiler operation.

What Is a Flue-Gas Economizer For?

It recovers heat from combustion gases to preheat the feedwater, resulting in fewer calories lost up the stack and several points of overall efficiency gain.

Is the Regulatory Framework for a Steam Boiler Complicated?

There is a strict framework: the European Pressure Equipment Directive and the French order requiring periodic inspections and controls. These obligations are handled by approved inspection bodies. The operator simply ensures that inspections and tests are performed on schedule.